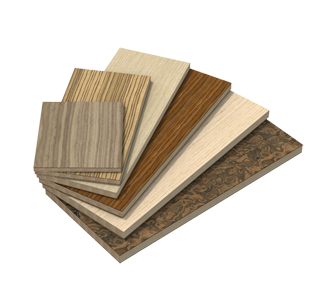

Melamine Chipboard Panels

Thickness: 8 – 10 – 12 – 16 – 18 – 19 – 20 – 25 – 30 mm

Particleboard, or chipboard, is the name of showing, commonly, the panels of wood fiber consisting of chips resulting from the difference of the normal workings of the wood. The wood chips are mixed with binder materials and then pressed to produce the panels; the panels obtained can be of different types depending on the type of chip. Glues can also be added to water-repellent agents, fungicides, flame retardants, etc.. (Source Wikipedia )

MDF

Thickness: 3 – 4 – 5 – 6 – 8 – 10 – 12 – 14 – 16 – 19 – 25 – 30 – 35 – 40 – 45 – 45 – 50 mm

The Medium-density fibreboard (MDF initials), translated as “medium density fibreboard”, is a derivative of wood . It is the most famous and widespread family of fiber panels, comprising three distinct categories based on the process used and the density: low (LDF), medium (MDF) and high (HDF). (Source Wikipedia )

OSB

Thickness: 6 – 9 – 12 – 15 – 18 – 22 – 25 – 30 – 40 mm

OSB panel or lamellar oriented thin and long, it is the board derived from wood that has known piœ strong growth of recent years. The building professionals who are familiar with his name and his special appearance. However, investigations have shown that many people do not yet know its capabilities and underestimated its potential -they pass close to one of the building materials piœ versatile and economical today. (Source OSB-INFO )

Panels Chipboard

Thickness: 10 – 12 – 14 – 16 – 20 – 22 – 25 – 28 – 30 – 38 – 50 mm

Particleboard, or chipboard, is the name of showing commonly panels in wood fiber compounds of chips resulting from the difference of the normal workings of the wood. The wood chips are mixed with binder materials and then pressed to produce the panels; the panels obtained can be of different types depending on the type of chip. Glues can also be added to water-repellent agents, fungicides , flame retardants, etc.. With the same name you can also specify the woody material base, ie the agglomeration of chips used to produce such panels. (Source Wikipidia )

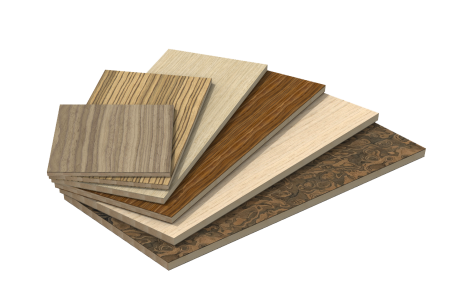

Panels Plywood And Plywood

Thickness: 3 – 4 – 5 – 6 – 8 – 10 – 12 – 15 – 18 – 20 – 25 – 30 mm (dipende dai colori)

Such panels are composed precisely by a number of more or less thin layers of wood: from a few tenths of a millimeter up to some millimeters. The layers are obtained mainly in two ways: by means of turning (legnoderullato) or by slicing (wood veneer).Such operations are performed directly on the tree trunks, using machines of considerable size.

Often the two terms “compensated” and “multilayer” are confused between them and erroneously considered synonyms: especially at the commercial level, the term “offset” is used (improperly) to indicate panels with thin layers and up to a certain thickness, while the term “multi-layer” is used to indicate panels of other thicknesses and with thicker layers. Properly for plywood panel means a panel composed of number three layers, of which the central one of greater thickness; a multilayer panel is composed of 5 or more layers. In both cases, the veins are orthogonally oriented. (Source Wikipedia )

Laminated Panels

Thickness: 11 – 14 – 18 – 19 – 20 – 24 – 27 – 32 – 35 – 40 – 42 mm (It depends on the finishes)

the laminated wood is a very solid and durable structural material produced by gluing the wooden boards in turn classified for structural use. This wood before being glued must be righettato so as to keep the glue solidly and univocally. It is therefore a composite material, consisting essentially of natural wood, of which maintains its quality (between the main remember the high ratio between mechanical strength epeso and good behavior in case of fire), but it is also a new product, realized on scale industrial, that through a technological process of bonding pressure reduces defects proper to the solid wood. (Source Wikipedia)

Panels Veneers

Thickness: 5 – 6 – 8 – 9 – 10 – 11 – 12 – 14 – 15 – 16 – 18 – 20 – 25 – 28 – 30 mm (It depends on the finishes)

The veneered panels are coated on both sides with fine wood veneers. The lists of veneer stretched before being applied on the support raw (hardboard, plywood and particle board), are joined by strands of glue longitudinal and transverse.

Panels Listellare

Thickness: 15 – 16 – 18 – 19 – 25 – 30 – 40 mm (It depends on the finishes)

The strip panel is constituted by a laminated or laminated wood coated on each of the two faces of two layers of peeled at superimposed parallel fiber. The strips of the soul are joined by glue, and have a maximum width of 33 mm.